It’s important for metal parts manufacturers to understand that, in many cases, it’s impossible to prevent corrosion forever. This is especially true for parts that are exposed to extremely harsh environmental conditions. Fortunately, zinc plating can extend the time before corrosion starts to appear. And YOU can play an important role in this process.

As you might know, zinc plating protects the base metal by “sacrificing” itself for the metal. When exposed to harsh conditions (such as in a marine or road salt environment). the zinc forms a protective layer of mainly zinc carbonate. After the protective film is formed, it resists attack by salt and other elements and ensures long-term corrosion protection.

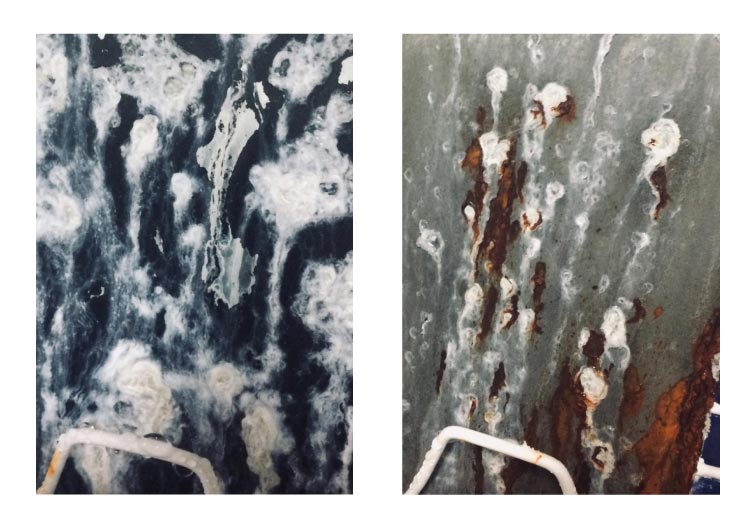

If conditions are severe enough for a long enough period of time, however, corrosion is ultimately inevitable – even with the best possible zinc plating. There’s a three-stage sequence to the corrosion process. The first stage is that the passivates, top coats and sealers that are applied on top of the zinc plating will turn black in a product barrier reaction. As this causes the passivates, base coats and sealers to disappear, the zinc will start to protect the base metal by sacrificing itself and corroding. This is the second stage of the process. And when the zinc is finally gone, the metal will generally start to corrode, which is the third and final stage.

The photo on the left shows the transition from the first stage to the second: the black indicates the reaction of the passivate, and the white indicates the corroding zinc. The base metal is not corroding at this stage because the zinc is sacrificing itself. The photo on right shows the transition from the second stage to the third: the white indicates the corroding zinc just before it disappears, and the red indicates the base metal as it starts to corrode.

So. . . What can YOU do to help your zinc plating do the best possible job of protecting your parts? It’s fairly simple: Once you receive your plated parts, store them in a way that protects them from harsh weather and humidity. If they’re stored outdoors, keep them covered with a tarp to keep rain, snow and animals out. If you don’t, the corrosion process may begin even before your parts are shipped to your customers and in use in the field.