Seasonal Tips: How to Protect Your Parts from Summer Humidity

Think of it this way, to test the protection that zinc provides, zinc plated product is subjected to a constant barrage of salt and water in the form of mist in a salt spray chamber. This mist is constant to accelerate the corrosion process so that test results are available within a week or two. There are two components that make up this test and accelerate the corrosion process: salt and water. While the air in the warmer months is no more salty than usual, it is the water component that can prove troublesome for zinc plated parts and lead to early white corrosion.

Contrary to popular belief, in the eyes of a zinc plater, white corrosion is not a bad thing. White corrosion means the zinc is doing its job, sacrificing itself to protect the base material. While white corrosion is an indication of well plated product, it is also an indicator that the next step is not far behind, red corrosion. Red corrosion is the base material corroding, and this corrosive process should be postponed for as long as possible, which often proves difficult where excess moisture and humidity is concerned.

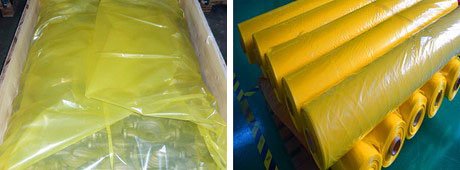

To avoid premature corrosion, Plateco would suggest storing product in open containers in moisture-controlled areas or within VCI (Vapor Corrosion Inhibitor) bags. Moisture controlled areas will reduce the amount of water in the air and VCI bags will help reduce the amount of water that has access to plated parts. VCI bags are a poly packaging film that forms a thin, invisible layer of protection to reduce moisture and contaminants that come into contact with product. It may help to think of it similarly to the silicon dioxide packets that come in a bag of beef jerky. These packets keep moisture away and preserves the jerky for long periods without mold, similar to VCI bags keeping parts from corroding. While VCI bags are extremely helpful to zinc plated product, any type of storage that allows for proper air flow and will not trap moisture is beneficial.

Remember, people do not perform well in excess humidity and neither does zinc. To avoid premature corrosion that naturally comes with the warmer weather, store zinc plated product in temperature and moisture-controlled areas with proper air flow. While we may enjoy the warmer weather, your zinc plated product does not.

For more tips and tricks to keep your product performing well, please message sales@plateco.net.