Hot Dipping Isn’t Always Cool

We have a lot of parts manufacturers ask us if we do hot dip galvanizing. Our usual response: We don’t, because we offer something that is very often a better solution – mechanical galvanizing.

It’s generally accepted that mechanical galvanizing often provides at least as much zinc protection as hot dip galvanizing, while being superior in many ways. Numerous tests conducted in accordance with ASTM B117 show that parts mechanically galvanized to a thickness of one once per square foot typically last at least 300 hours, while parts that have been galvanized using hot dipping often do not.

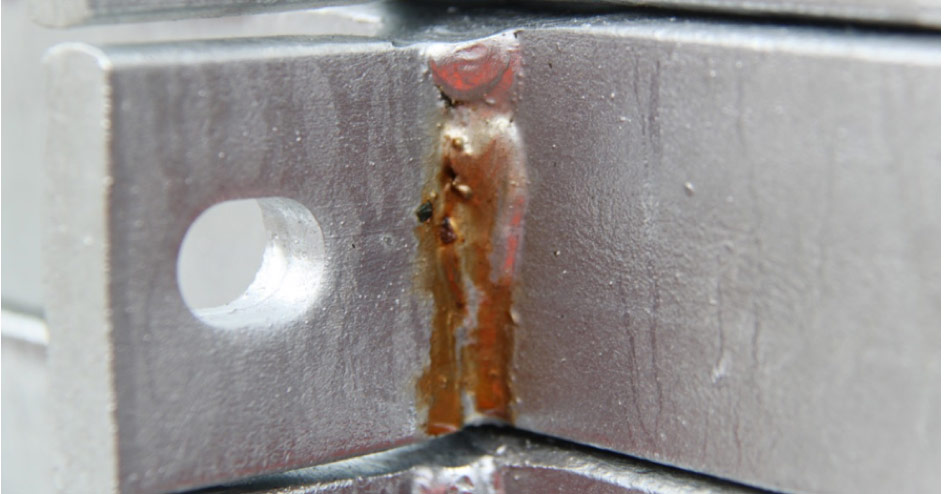

Of equal concern is the fact that parts that have been hot dip galvanized will sometimes exhibit severely premature red rust. (See photo below.) This is widely attributed to “interlayer corrosion” – the corrosion of the iron-zinc layer between the substrate and the galvanized coating.

In addition, hot dip galvanizing can exhibit a great deal of thickness variability, which results in some parts lasting a long time while other parts fail prematurely. Neither of these problems exist with mechanical galvanizing.

Other advantages of mechanical galvanizing over hot dip galvanizing:

- No need for hydrogen embrittlement relief.

- No risk of de-tempering. The heat from hot dip galvanizing can negate the tempering process that increases the hardness and toughness of the metal when the part is manufactured.

- Better thread fit between fasteners and chasing nuts. Mechanical galvanizing does not fill the “valleys” of threaded fasteners, which allows the fasteners and nuts to mate easily and quickly. This isn’t the case with hot dip galvanizing.

- No galling. Because of the naturally lubricious nature of zinc mechanical galvanizing coatings, there will be no galling (i.e., no wear caused by adhesion between sliding surfaces). This will produce more accurate torque-tension relationships than with hot dip galvanizing.

- No stickers. In hot-dip galvanizing, molten zinc often fuses parts together, resulting in lost time, effort and materials as well as the need for extra assemblies. This isn’t a problem with mechanical galvanizing.

- Better adhesion.

Hot dips can be great when they take the form of a chili con queso to go with your favorite tortilla chips. But when it comes to zinc plating, hot dip galvanizing may leave you cold compared to the superiority of mechanical galvanizing.