Avoid This Trap!

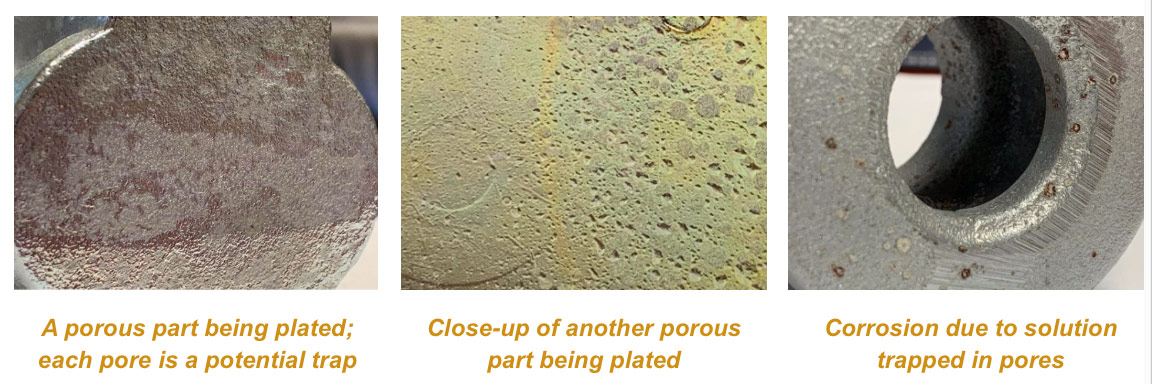

Did you know that the porosity of your part’s substrate can cause our processing solution to get trapped within the part and cause plating issues? Here’s how it can happen.

When we process a part, it’s submersed into a heated tank (typically an acid or soap solution), causing the part and any pores to expand and fill with our solution. We then submerse it into a cooled tank (often a rinsing tank), which causes the part and any pores to contract and trap solution into the part’s surface.

These traps can cause issues with how our zinc plating adheres to the part over time, as the solution trapped inside the substrate’s pores will eventually work its way out and could create corrosion issues.

Unfortunately, no change to the plating process can prevent this from happening to a part that’s highly porous.

However, there is something YOU can do: Reduce the pores — and hence the potential for “traps” — in your part’s substrate by using a polishing or blasting procedure.

It might seem like a bit of a hassle, but it will be a lot less hassle than dealing with parts that fail in the field due to porosity-induced plating failures. And your parts’ finish will be more uniform and chrome-like, too!