Casting Doubt

- Highly porous substrate

- Rough substrate surface

- Impurities in the casting

Highly Porous Substrate

Substrate porosity can cause our process solution to get trapped within the part when it’s being processed. (An example of a highly porous substrate is on the right.)

When we process a part, we almost treat parts like a lung. We will submerse a part into a heated tank (typically an acid or soap), causing the part (and any pores) to expand and fill with our solution. Then the part will be submersed into a cooled tank (like a rinse tank), which will cause the part (and any pores) to contract and trap any solutions into the surface of the product. As time passes, the solution that was trapped in the substrate pores will work its way out and reduce the zinc’s adhesion to the casting.

The best way to avoid this problem: Reduce the porosity of the substrate by machining, polishing or blasting the castings before sending them to be plated.

Rough Substrate Surface

Surface roughness can be an issue when trying to reliably calculate the surface area of a casting. When a part needs to be plated to a desired thickness – say 0.0003″ – we calculate the casting’s total surface area and then apply a formula to determine the precise ASF (amps per square foot) that will yield the desired thickness.

A rough substrate is problematic in two ways:

1. It increases the surface area of the casting, which increases the required ASF and hence the cost.

2. Because the degree of roughness can vary widely between each lot, it’s likely that the surface area of the castings we measure will be either more or less than previous orders. That means that the amount of power required can very significantly from order to order.

The best way to avoid this problem is once again to reduce the roughness of the substrate by machining, polishing or blasting the castings before sending them to be plated.

Impurities in the Casting

There are some impurities that may be on the surface of the casting that can affect the adhesion of plating. If any sand from the sand mold remains on the casting’s surface after being removed from the mold, this could affect the plating quality as zinc doesn’t adhere to sand. To prevent sand from adhering to the casting’s surface, you can utilize media that may either be blown with compressed air or hurled using a shot wheel.

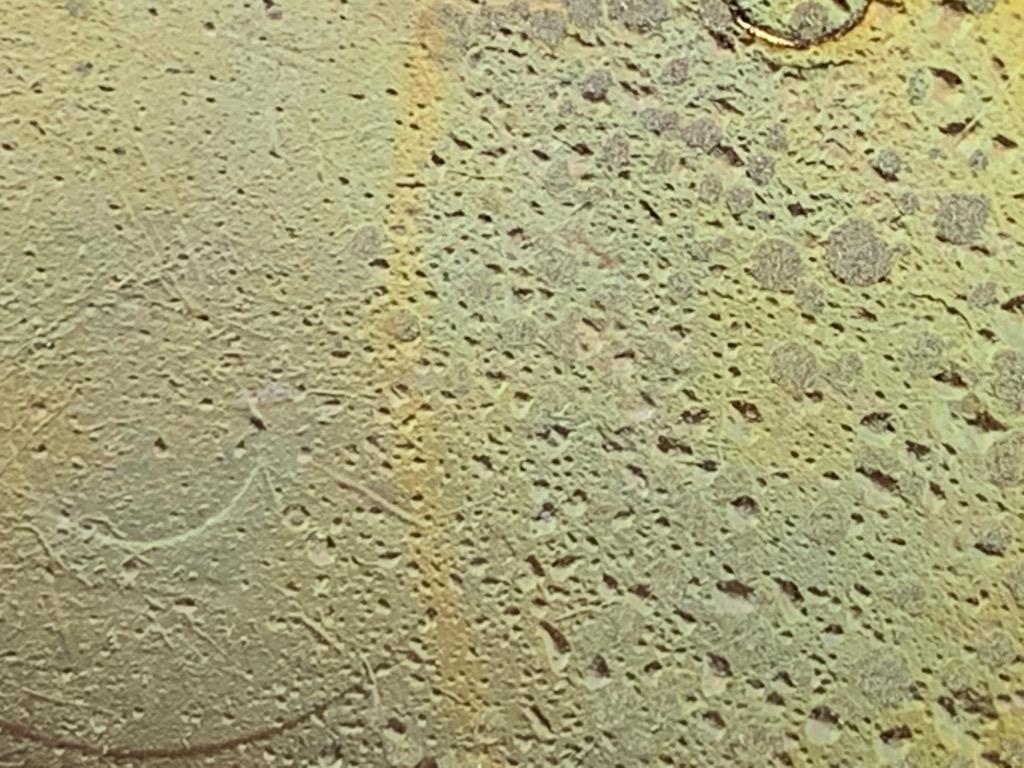

If a casting is made with a lower grade of steel alloys, also known as pot metal, using these alloys could also affect the quality of zinc plating. (An example of such a casting is on the right.) Depending on the exact metals “thrown into the pot,” pot metal can become unstable over time since it has no metallurgical standard. This metal has a tendency to bend, distort, crack, shatter, and pit with age. In addition, many components common in pot metal are susceptible to external corrosion from airborne acids and other contaminants that prevent the zinc plating from adhering, as well as to internal corrosion of the metal.

Since the pot metal materials in castings are often inconsistent, there can be large amounts of impurities left in or on the surface during the manufacturing process that take a good amount of cleaning by the plating company to remove. However, it’s important that the plater not clean the product excessively, as this can draw carbon to the surface of the product and leave a carbon-rich surface on the casting. Because zinc does not adhere to carbon, there will be areas that are un-plateable.

To avoid this problem, we encourage you to ensure that your castings are manufactured with sufficiently high quality steel alloys.